|

|

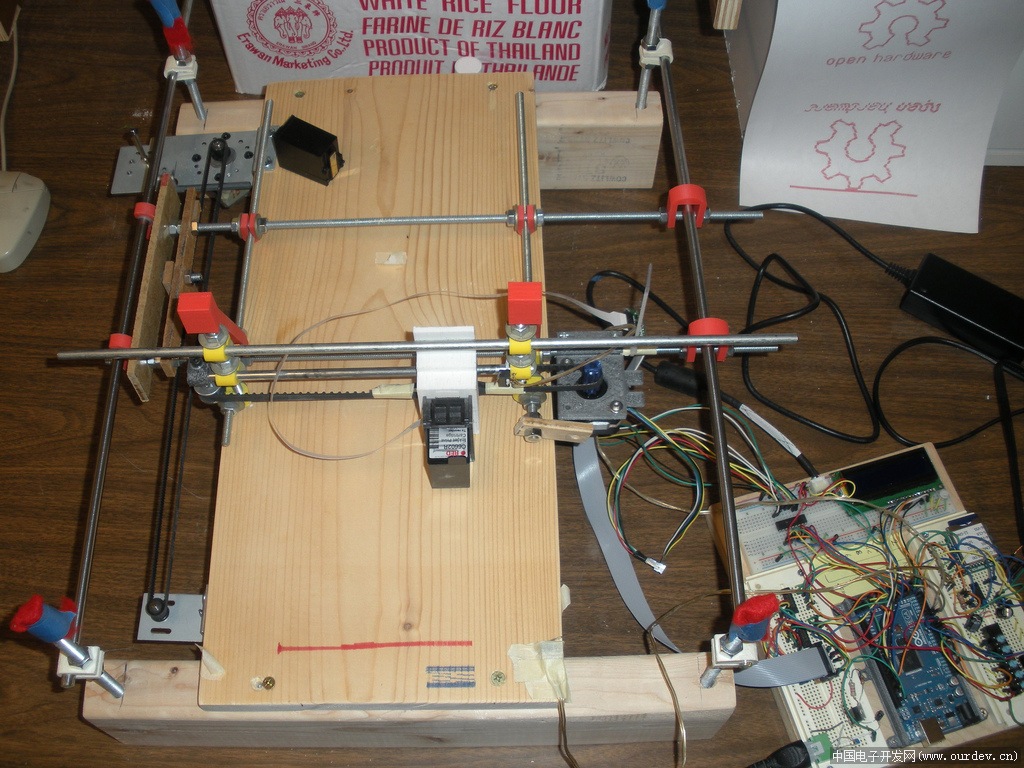

喷墨墨盒 HP 51604A 96 dpi

(原文件名:未命名.jpg)

点击此处下载 ourdev_714183MSF9LD.pdf(文件大小:1.56M) (原文件名:DIY_Inkjet_Printer.pdf)

(原文件名:5725270514_5972818238_b.jpg)

haracteristics of the pulses, and many other limitations regarding the triggering pulses,

are mentioned in Gilliland’s book [1].

The optimum firing energy of the print cartridge is about 40 microjoules. This

means that the pulse width can be equated to the voltage using the following equation:

2

2

65 0.00004

voltage

pulsewidth

voltage

pulsewidth resista ce energy











Gilliland has calculated this for the optimum values for this, and provides this

table (the pulse widths have been rounded to the nearest half microsecond) [1]:

Table 1: The firing times at different voltages

Since these are described as the optimum pulse widths, it may be possible to

change the pulse widths so they do not exactly match up with data in the table; Gilliland

states that changing the pulse times may be an option, but that performance may drop [1].

He goes on to elaborate, saying that reducing the pulse time could result in poor droplet

quality and clogged nozzles, while too long a time (and energy) could burn out the

resistors [1].

Gilliland also notes that with the extremely short pulse times, it might be better to

use a lower voltage with a longer pulse time, increasing the amount of control the

Voltage Pulse width

(V) DC (μs)

20 6.5

21 6

22 5.5

23 5

24 4.5

Generated by Foxit PDF Creator © Foxit Software

http://www.foxitsoftware.com For evaluation only.

programmer has on the pulse width. The reason for this is that at such short timespans,

the microcontrollers processing time becomes a significant factor; for example, the

arduino board takes approximately 3 to 4 μs to turn an output pin on and off with no

commands between the on and off commands. This means that, since the microcontroller

being used is the arduino, the voltage cannot be over about 26 volts (and may run into

some difficulties at 24 volts) [1].

Gilliland recommends that the time between the same nozzle being fired twice

should be at least 800 μs [1]. This criterion is based on the time taken for the ink to refill

in the chamber, and any firing at a faster frequency will result in poor quality printing.

The HP 51604A specification sheet states that up to two nozzles, and no more,

can be fired simultaneously. Gilliland suggests that this is because of the limit on the

energy that the conductors within the print cartridge can effectively deliver. Gilliland

also says that two adjacent nozzles cannot be fired simultaneously, as this will give

unpredictable results. This is probably because the droplets would interact, and could end

up some distance from the intended target based on the relative velocities of the droplets.

Gilliland goes on to suggest that maximising distance between nozzles being fired at the

same time will give the best and most reliable performance [1].

The dead time, or the time between firing two pairs of nozzles, according to

Gilliland, is 0.5 μs [1]. Although Gilliland does not explicitly state a reason, it is likely to

be because this is the minimum gap required to prevent the aforementioned issues of

energy limits on the circuitry and interference between droplets.

A lot of these specifications will not cause the printer to fail, but will adversely

affect the print quality. Gilliland makes a significant effort to emphasise that print quality

is entirely subjective, and that the designer must decide whether the quality of the

printing is good enough for the given application [1]. |

阿莫论坛20周年了!感谢大家的支持与爱护!!

月入3000的是反美的。收入3万是亲美的。收入30万是移民美国的。收入300万是取得绿卡后回国,教唆那些3000来反美的!

|